MB-70

MB-70 is a modern aluminium system used for exterior architectural elements requiring thermal and acoustic insulation, e.g.: various types of windows, doors, vestibules, showcases and spatial structures.

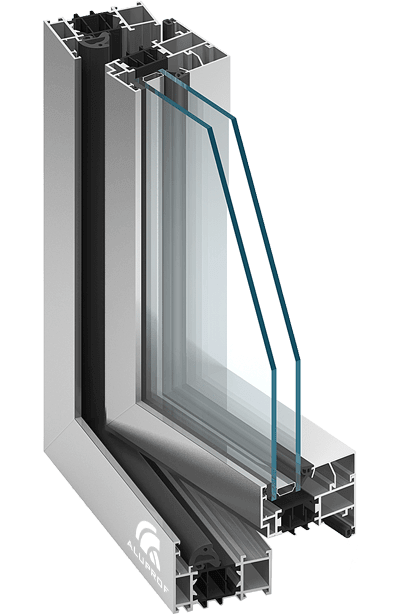

The system profiles have a three-chamber construction. The structural depth of the window sections is: 70 mm (frame), 79 mm (leaf), and door: 70 mm and 70 mm. These adopted depths of the leaf and frame sections give the effect of a single plane on the external side when closed – in the case of a window - and the effect of flush leaf and frame surfaces – in the case of a door. The shape of the profiles makes it possible to achieve slim and robust window and door constructions.

The system profiles have a three-chamber construction. The structural depth of the window sections is: 70 mm (frame), 79 mm (leaf), and door: 70 mm and 70 mm. These adopted depths of the leaf and frame sections give the effect of a single plane on the external side when closed – in the case of a window - and the effect of flush leaf and frame surfaces – in the case of a door. The shape of the profiles makes it possible to achieve slim and robust window and door constructions.

The MB-70 system is characterised by a sensationally low heat transfer coefficient U due to the use of special thermal breaks and gaskets. This is important in an era of increasing energy management and environmental requirements. The Uf coefficient for the MB-70 system construction ranges from 1.5 to 2.39 W/(m2K), depending on the profiles and accessories used. The system uses profiled omega-shaped thermal breaks 34 (windows) and 24 (doors) mm wide made of glass fibre-reinforced polyamide. The shape of the spacer breaks increases the rigidity of the profiles compared to flat spacers and facilitates the drainage of sections, thus ensuring proper thermal insulation in all weather conditions. Thermal breaks used in windows have an additional seal at the junction between the section and the break and projections dividing the chamber between the inner and outer aluminium sections into three parts. Tightness is ensured by the use of special seals made of two-component EPDM synthetic rubber: solid and cellular, which guarantees resistance to ageing during many years of operation and very good thermal insulation. MB-70 is the first system to use this type of material for the central seal.

The MB-70 system is characterised by a sensationally low heat transfer coefficient U due to the use of special thermal breaks and gaskets. This is important in an era of increasing energy management and environmental requirements. The Uf coefficient for the MB-70 system construction ranges from 1.5 to 2.39 W/(m2K), depending on the profiles and accessories used. The system uses profiled omega-shaped thermal breaks 34 (windows) and 24 (doors) mm wide made of glass fibre-reinforced polyamide. The shape of the spacer breaks increases the rigidity of the profiles compared to flat spacers and facilitates the drainage of sections, thus ensuring proper thermal insulation in all weather conditions. Thermal breaks used in windows have an additional seal at the junction between the section and the break and projections dividing the chamber between the inner and outer aluminium sections into three parts. Tightness is ensured by the use of special seals made of two-component EPDM synthetic rubber: solid and cellular, which guarantees resistance to ageing during many years of operation and very good thermal insulation. MB-70 is the first system to use this type of material for the central seal.

The system allows for glass packets with a thickness of 21 mm to 57 mm in window leaves and 12 mm to 48 mm in fixed windows and door leaves. This wide range of infill thicknesses ensures that all typical and non-standard glazing can be used.

The large selection of colours in the standard palette makes it possible to meet the needs of the most demanding customers. Colour coatings are made by powder coating or anodising. The MB-70 system is the basis for solutions with enhanced thermal insulation: MB-70 HI, MB-70US HI and a cold-warm façade based on MB-70CW HI windows.

The system also enables the construction of burglar-proof window and door structures in the following classes: RC1 - RC3 and MB-70RC4 windows with the highest burglary resistance in the RC4 class.

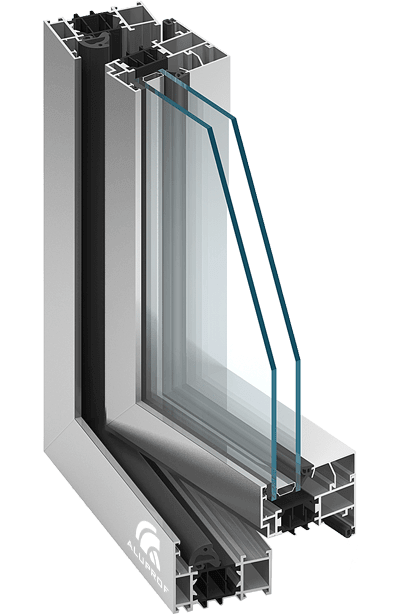

The system profiles have a three-chamber construction. The structural depth of the window sections is: 70 mm (frame), 79 mm (leaf), and door: 70 mm and 70 mm. These adopted depths of the leaf and frame sections give the effect of a single plane on the external side when closed – in the case of a window - and the effect of flush leaf and frame surfaces – in the case of a door. The shape of the profiles makes it possible to achieve slim and robust window and door constructions.

The system profiles have a three-chamber construction. The structural depth of the window sections is: 70 mm (frame), 79 mm (leaf), and door: 70 mm and 70 mm. These adopted depths of the leaf and frame sections give the effect of a single plane on the external side when closed – in the case of a window - and the effect of flush leaf and frame surfaces – in the case of a door. The shape of the profiles makes it possible to achieve slim and robust window and door constructions.

The system allows for glass packets with a thickness of 21 mm to 57 mm in window leaves and 12 mm to 48 mm in fixed windows and door leaves. This wide range of infill thicknesses ensures that all typical and non-standard glazing can be used.

The large selection of colours in the standard palette makes it possible to meet the needs of the most demanding customers. Colour coatings are made by powder coating or anodising. The MB-70 system is the basis for solutions with enhanced thermal insulation: MB-70 HI, MB-70US HI and a cold-warm façade based on MB-70CW HI windows.

The system also enables the construction of burglar-proof window and door structures in the following classes: RC1 - RC3 and MB-70RC4 windows with the highest burglary resistance in the RC4 class.

EN

EN PL

PL DE

DE