Types of glass

Float - colourless

Float - colourless Venetian mirror

Venetian mirror Coloured graphite

Coloured graphite Milk

Milk

The main advantages of toughened glass are its high impact and temperature resistance, the flexibility of the material and safety in the event of breakage. All these characteristics make toughened glass an excellent material for creating both large glass structures and doors, as well as furniture elements such as shelves and tabletops.

The main advantages of toughened glass are its high impact and temperature resistance, the flexibility of the material and safety in the event of breakage. All these characteristics make toughened glass an excellent material for creating both large glass structures and doors, as well as furniture elements such as shelves and tabletops. Float - colourless

Float - colourless Venetian mirror

Venetian mirror Coloured graphite

Coloured graphite Milk

Milk 8 mm

8 mm 10 mm

10 mm 12 mm

12 mm all-glass doors and interior fittings

all-glass doors and interior fittings balustrades

balustrades coffee tables

coffee tables shelves

shelves panele kuchenne

panele kuchenne balustrades

balustrades countertops

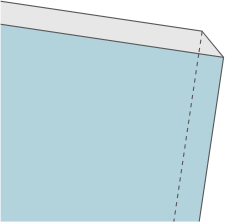

countertops collapsed edges

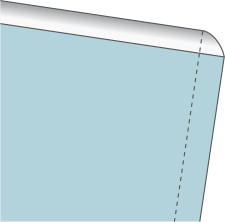

collapsed edges C-edge

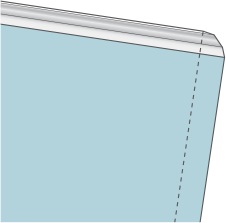

C-edge sanded edges

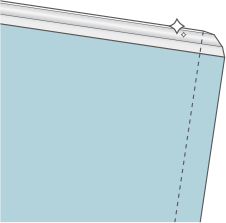

sanded edges sanded and polished edges

sanded and polished edgesOther glass types and finishes available on request.