Ideal 7000

Modern architecture requires new standards in the technical, functional and aesthetic spheres. The changing legal requirements for joinery and, above all, the expectations of customers looking for ever warmer windows are trends that cannot be ignored.

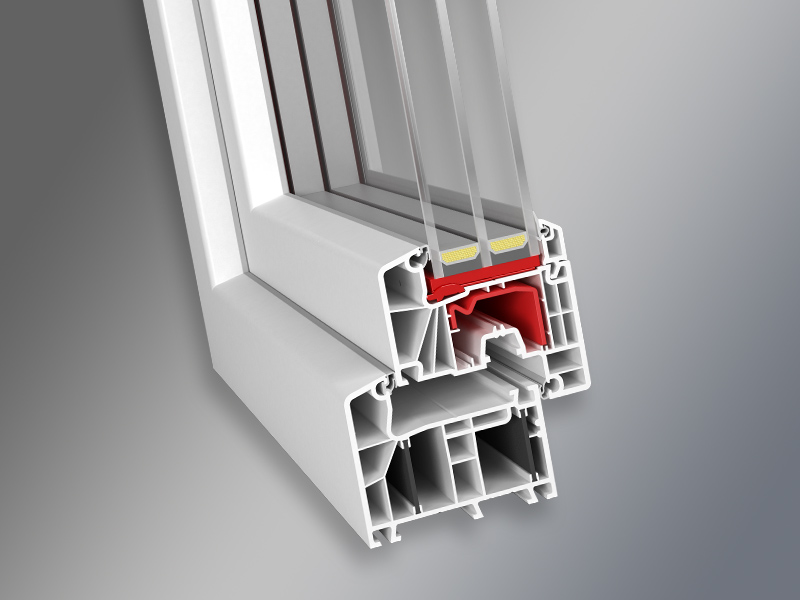

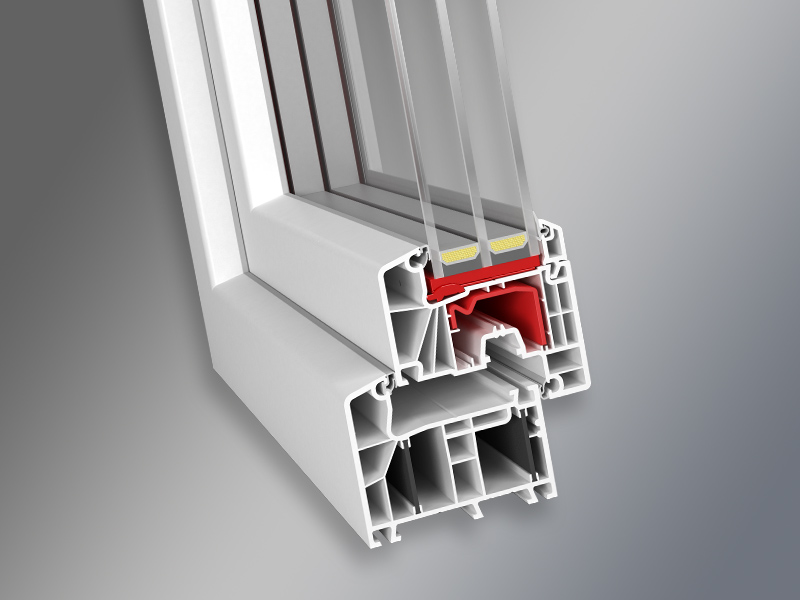

It is an externally sealed system, which makes it possible to offer an energy-efficient solution also for fixed-glazed structures without the need for adapters. A large chamber with solid steel reinforcement is a guarantee for the stability of the frame. The system allows frames to be freely combined with other profile series with a depth of 85 mm. It is an externally sealed system, which makes it possible to offer an energy-efficient solution also for fixed-glazed structures without the need for adapters.

The Ideal 7000 series is a multifunctional system, using MULTIFALZ technology, which is an option for the use of glaze bonding technology. Thanks to the new glazing rebate geometry, it is possible to produce conventional as well as glaze bonding. These technologies can be used interchangeably or combined as required, e.g. it is possible to improve the thermal properties of a structure by eliminating steel reinforcements and glaze bonding, or to use both steel reinforcement and glaze bonding technology for larger window sizes, colours etc. The optional use of glaze bonding technology, on the other hand, allows the windows to be even more stable. With permanent bonding of the glass and the leaf, the risk of warping, bending and settling of the leaf is reduced, thereby extending the service life life of the leaf without adjustment.

Just as the world around us is becoming more and more colourful, the popularity and market share of coloured windows is gradually increasing. Colour preferences are also clearly changing, with anthracite, basalt and various shades of grey beginning to dominate in particular.

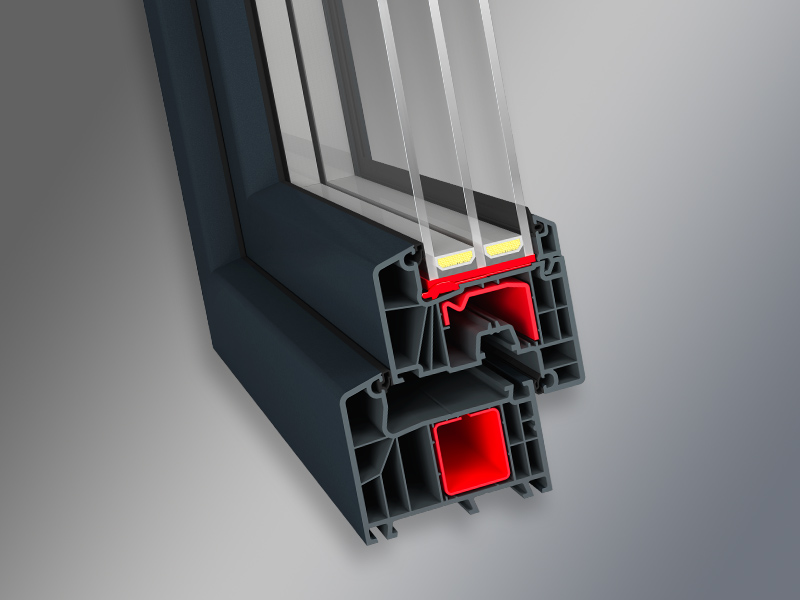

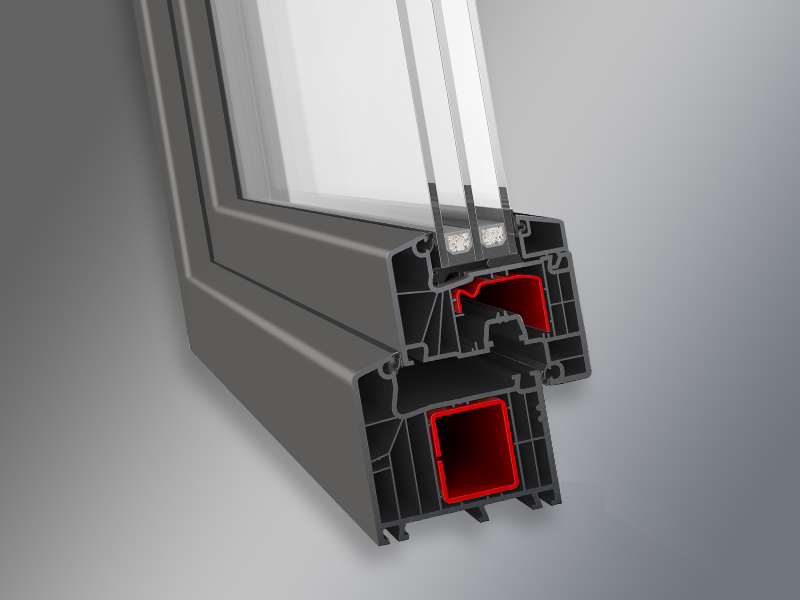

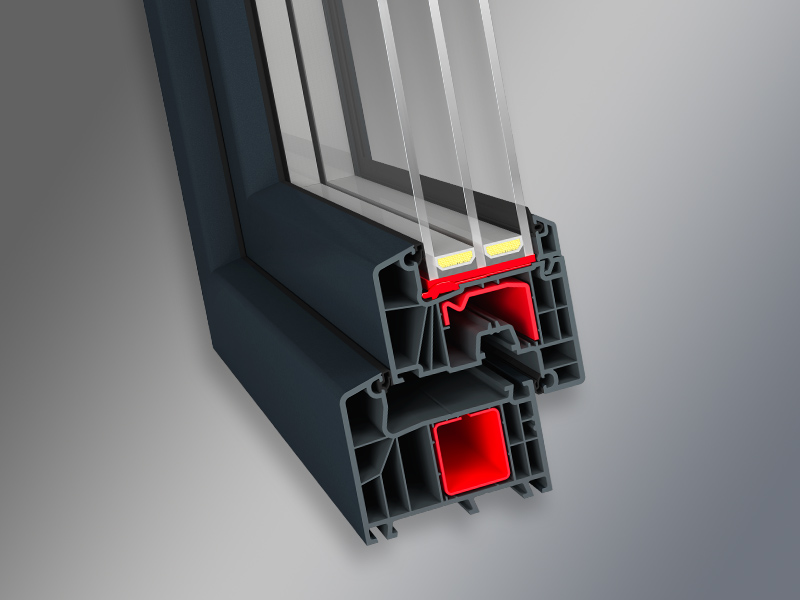

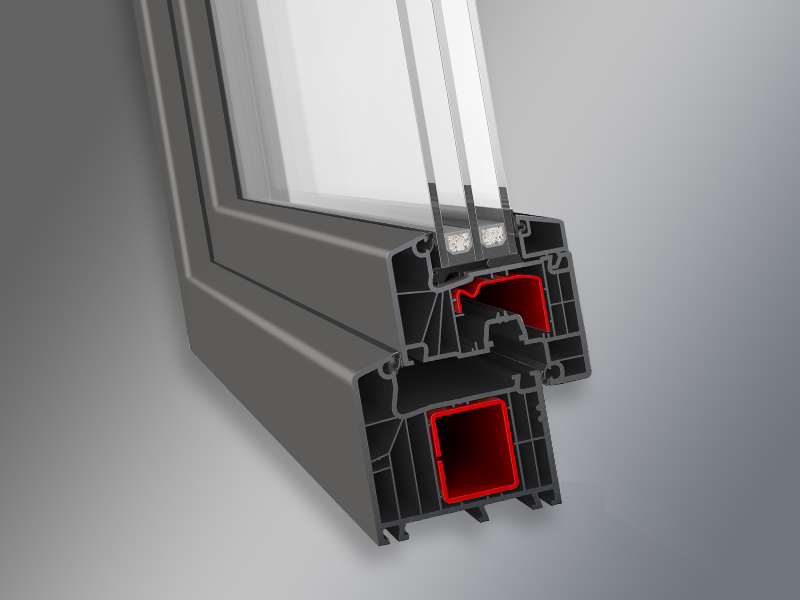

The way we think about architecture has clearly been changing in recent years. This is reflected above all in the search for solutions, both in the design of the building and in the products used in it, to give these buildings a unique and individual character. Responding to these trends, we are introducing profiles with an anthracite core, which will allow the windows to fit even better into fashionable and modern arrangements. The anthracite core makes it possible, in the case of windows with double-sided veneering, to achieve a uniform colour across the entire profile cross-section. In this way, the windows blend in even better with modern interior and façade designs.

The way we think about architecture has clearly been changing in recent years. This is reflected above all in the search for solutions, both in the design of the building and in the products used in it, to give these buildings a unique and individual character. Responding to these trends, we are introducing profiles with an anthracite core, which will allow the windows to fit even better into fashionable and modern arrangements. The anthracite core makes it possible, in the case of windows with double-sided veneering, to achieve a uniform colour across the entire profile cross-section. In this way, the windows blend in even better with modern interior and façade designs.

The IDEAL 7000 is an excellent example of a hybrid solution in which we enlarge the depth of the profiles to 85 mm, increase the number of chambers, and enable the glazing of energy-efficient glass packets with a width of 51 mm, while at the same time eliminating steel reinforcements, i.e. elements that have a negative impact on the thermal properties of the structure. Fibreglass-reinforced thermoplastic replaces the steel used in conventional PVC window frames and provides significantly better thermal insulation properties with the same mechanical properties of the window.

The IDEAL 7000 is an excellent example of a hybrid solution in which we enlarge the depth of the profiles to 85 mm, increase the number of chambers, and enable the glazing of energy-efficient glass packets with a width of 51 mm, while at the same time eliminating steel reinforcements, i.e. elements that have a negative impact on the thermal properties of the structure. Fibreglass-reinforced thermoplastic replaces the steel used in conventional PVC window frames and provides significantly better thermal insulation properties with the same mechanical properties of the window.

By eliminating steel reinforcements from the Ideal 7000 “Powerdur inside” series profiles, thermal bridges are reduced and the heat transfer coefficient of the frames for this series is Uf=1.0W/m2K, a very good result for a system with external sealing. At the same time, the design of the profiles makes it possible to further improve the thermal permeability of the sections by optionally filling the spaces of some internal chambers with heat-insulating material.

This is very good news in the context of technical requirements to be met by buildings and their location, introducing stricter standards for window joinery and specifying the minimum thermal insulation coefficient at Uw(max)=1.1W/(m2*K), from 1J January 2017 and Uw(max)=0.9 W/(m2*K)) from 1 January 2021.

Improving the thermal properties was undoubtedly one of the primary objectives in designing this system, but eliminating steel reinforcements from the frames also brings a number of additional benefits to window manufacturers in the form of improved production processes, by: reducing the processes involved in storing, cutting and screwing in steel reinforcements, as well as less wear and tear on steel cutting saws.

* the performance values given are the maximum values achieved in the tests

A new dimension in energy efficiency

The IDEAL 7000 is an example of the synergistic use of the properties of profiles and insulating glass to create windows characterised by very low thermal transmittance. The Uf = 1.1-1.0 W/m2K thermal transmittance coefficient of the profiles, combined with the possibility of using wider and warmer glass packets with a width of up to 51 mm, guarantees the best thermal parameters of the window.It is an externally sealed system, which makes it possible to offer an energy-efficient solution also for fixed-glazed structures without the need for adapters. A large chamber with solid steel reinforcement is a guarantee for the stability of the frame. The system allows frames to be freely combined with other profile series with a depth of 85 mm. It is an externally sealed system, which makes it possible to offer an energy-efficient solution also for fixed-glazed structures without the need for adapters.

The Ideal 7000 series is a multifunctional system, using MULTIFALZ technology, which is an option for the use of glaze bonding technology. Thanks to the new glazing rebate geometry, it is possible to produce conventional as well as glaze bonding. These technologies can be used interchangeably or combined as required, e.g. it is possible to improve the thermal properties of a structure by eliminating steel reinforcements and glaze bonding, or to use both steel reinforcement and glaze bonding technology for larger window sizes, colours etc. The optional use of glaze bonding technology, on the other hand, allows the windows to be even more stable. With permanent bonding of the glass and the leaf, the risk of warping, bending and settling of the leaf is reduced, thereby extending the service life life of the leaf without adjustment.

Pure elegance in anthracite

The Ideal 7000 profile series is available with an anthracite core for an even better aesthetic effect.Just as the world around us is becoming more and more colourful, the popularity and market share of coloured windows is gradually increasing. Colour preferences are also clearly changing, with anthracite, basalt and various shades of grey beginning to dominate in particular.

Anthracite core

Anthracite core

A new approach to energy efficiency – “Powerdur inside”

“Powerdur inside” is an innovative coextrusion technology for PVC profiles using special Ultradur® High Speed glass fibre-reinforced thermoplastic inserts, developed in cooperation with BASF. The IDEAL 7000 is an excellent example of a hybrid solution in which we enlarge the depth of the profiles to 85 mm, increase the number of chambers, and enable the glazing of energy-efficient glass packets with a width of 51 mm, while at the same time eliminating steel reinforcements, i.e. elements that have a negative impact on the thermal properties of the structure. Fibreglass-reinforced thermoplastic replaces the steel used in conventional PVC window frames and provides significantly better thermal insulation properties with the same mechanical properties of the window.

The IDEAL 7000 is an excellent example of a hybrid solution in which we enlarge the depth of the profiles to 85 mm, increase the number of chambers, and enable the glazing of energy-efficient glass packets with a width of 51 mm, while at the same time eliminating steel reinforcements, i.e. elements that have a negative impact on the thermal properties of the structure. Fibreglass-reinforced thermoplastic replaces the steel used in conventional PVC window frames and provides significantly better thermal insulation properties with the same mechanical properties of the window.By eliminating steel reinforcements from the Ideal 7000 “Powerdur inside” series profiles, thermal bridges are reduced and the heat transfer coefficient of the frames for this series is Uf=1.0W/m2K, a very good result for a system with external sealing. At the same time, the design of the profiles makes it possible to further improve the thermal permeability of the sections by optionally filling the spaces of some internal chambers with heat-insulating material.

Ideal 7000 “Powerdur inside” – advantages of hybrid solutions

The metal bracing in the window frame profiles creates a thermal bridge due to the high thermal conductivity. The extremely good mechanical properties of Ultradur High Speed make the material suitable for use in window frames. The use of Powerdur allows a marked improvement in the thermal properties of the profiles, which is largely related to the thermal conductivity of Ultradur High Speed, which is 50 times lower than that of steel.This is very good news in the context of technical requirements to be met by buildings and their location, introducing stricter standards for window joinery and specifying the minimum thermal insulation coefficient at Uw(max)=1.1W/(m2*K), from 1J January 2017 and Uw(max)=0.9 W/(m2*K)) from 1 January 2021.

Improving the thermal properties was undoubtedly one of the primary objectives in designing this system, but eliminating steel reinforcements from the frames also brings a number of additional benefits to window manufacturers in the form of improved production processes, by: reducing the processes involved in storing, cutting and screwing in steel reinforcements, as well as less wear and tear on steel cutting saws.

Technical specification – IDEAL 7000 system

| Depth of construction: | 85 mm |

|---|---|

| Width of frame/leaf combination: | 119 mm |

| Maximum glazing thickness: | 51 mm |

| Number of chambers: | 6 |

| Sealing system: | external |

| Reinforcement system: | steel, Ultradur High Speed reinforcement |

| Profile styles available: | Classic-line |

| Heat transfer coefficient: | Uf=1,0 - 1,1W/m2K |

| Wind resistance: | C4* |

| Water resistance: | 9A* |

| Air permeability: | 4* |

| Sound insulation with 4/16/4 glass packet: | 33(-2;-5)dB |

| Maximum sound insulation: | 46(-1;-4)dB* |

| Bonding inside technology: | no |

| Foaming capability: | no |

| Replaceable gaskets: | no |

| Compatible with product series: | Exterior doors 7000 |

EN

EN PL

PL DE

DE